Bits for Drilling Metal

Nearly any standard twist drill bit will suffice for making holes in metal. Actually, most such bits work quite well for this purpose. drill bits labeled specifically for metal are manufactured to drill through various materials, including wood and plastic. The least expensive twist bits are made of high-speed steel (HSS), and these basic bits are just fine for most metal-drilling tasks.

If you plan on drilling numerous holes or tackling tough materials such as stainless steel or cast iron, invest an extra few dollars in a black oxide or cobalt steel drill bit designed specifically for metal. Such bits can withstand more wear before they become blunt. Additionally, some bits feature a specialized coating known as titanium nitride (TiN). Manufacturers assert that this coating enhances resistance against heat and friction, potentially extending the life of these bits up to six times compared to conventional high-speed steel bits.

Make a Dimple

Drill bits often veer off course at the beginning of drilling. To avoid this, take measurements and make markings indicating where you intend to drill holes. Next, utilize a center punch along with a hammer to form a tiny indentation. This allows the end of your drill bit to stay within the designated area as you commence drilling.

Lubricated Drill Bits

When drilling holes in steel that is 1/8 inch thick or more, apply cutting fluid or a multipurpose oil . Lubricating the bit reduces friction and heat buildup, which makes drilling easier and your bits last longer.

For softer metals such as aluminum, brass, or cast iron, which are generally simpler to drill through, lubrication typically isn't required.

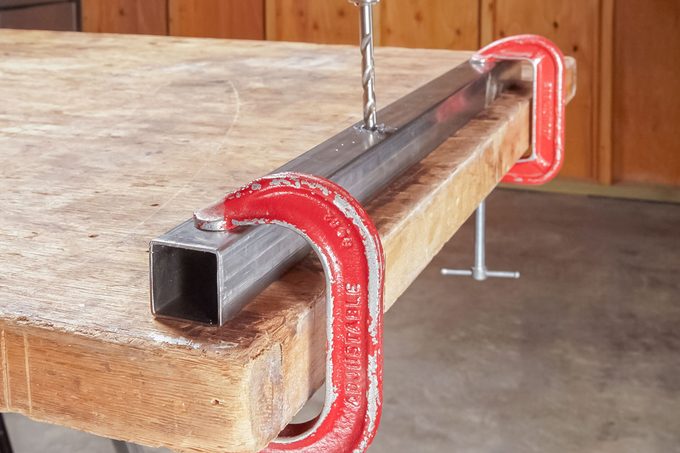

Use Clamps to Secure What You’re Drilling

Never hold a piece of metal in one hand while trying to drill through it with the other. The drill bit for metal could catch, instantly causing the workpiece to spin, strike and slash (sharp metal edges slice to the bone!). Always use a minimum of two clamps to secure your workpiece.

Begin with a Tiny Opening

Looking for a large hole? Begin small! Many twist bits come in diameters up to 1 inch, however, achieving optimal results involves starting with a 1/4-inch hole and gradually increasing the size using progressively larger drill bits designed for metal until you achieve your desired dimension.

Deburr the Hole

Once you've drilled a hole in metal, it’s advisable to eliminate any sharp edges or burrs remaining afterward.

If you're looking for a cost-effective solution to smoothen rough edges after drilling, consider using a drill bit trick instead of purchasing expensive deburring tools. Simply select a drill bit with a marginally wider diameter compared to your recently drilled hole. Then manually rotate this bit around the perimeter of the hole by hand. Doing so helps eliminate any jagged edges and removes excess material left behind from the drilling process.

Hole Saw Cuts Larger Openings

When dealing with larger openings, a hole saw accomplishes the task neatly and swiftly. Similar to twist drills, hole saws can be securely attached to your drill and will easily penetrate thinner metal gauges. sheet metals like aluminum and steel. Use a scrap of plywood as a backer for the hole saw’s pilot bit and to protect your work surface.

Practice at a Reduced Pace

The quicker a bit rotates, the more warmth it accumulates. This excess heat accelerates wear on the bit. Therefore, when drilling into metal, it’s advisable to use the lowest rotational speed feasible with a specialized drill bit designed for metalwork. Drilling harder materials such as steel or employing bigger drill bits demands an even lower speed setting. When working with smaller twist bits ranging from 1/16 inch to 3/16 inch, you can typically operate at around 3,000 revolutions per minute. However, for larger twist bits spanning from 11/16 inch to 1 inch, it's best to keep the rotation between 350 and 1,000 revolutions per minute.

Make a Sandwich

To create neat, accurate holes in thin sheet metal, construct a wood sandwich. Place the sheet metal between two boards and secure them with clamps onto a table or work surface. This method keeps the sheet metal stable and stops the drill bit from straying as it penetrates the material.

Try a Step Bit

Step drill bits are crafted specifically for drilling holes in sheet metal and similar lightweight materials. These tools come in handy whenever you require accurately sized, neat openings in items like steel junction boxes, electrical service panels, or perhaps a stainless-steel sink. With a step drill bit intended for metals, you can create holes with multiple diameter sizes, capable of penetrating metal as thick as 3/8 inch. However, one drawback is their higher cost compared to standard drill bits.

Upgrade to Using a Drill Press

Although it’s quite simple to bore most holes in metal with just a hand-held drill, you will typically achieve higher precision and superior outcomes by utilizing a drill press . Most drill presses are actually built with metalworking in mind. Pulling down on the handle causes the bit to plunge straight down into a workpiece and make a very precise hole.

Drill presses feature robust cast-iron worktables that offer adjustable tilting and height settings, along with multiple clamping possibilities. Changing speeds simply involves lifting the cover and shifting a rubber belt between different pulleys. While the priciest drill presses are standing units, you can obtain a reliable benchtop model for approximately $200 or somewhat under.

Next, discover How to bore a hole through a ceramic planter .

Post a Comment